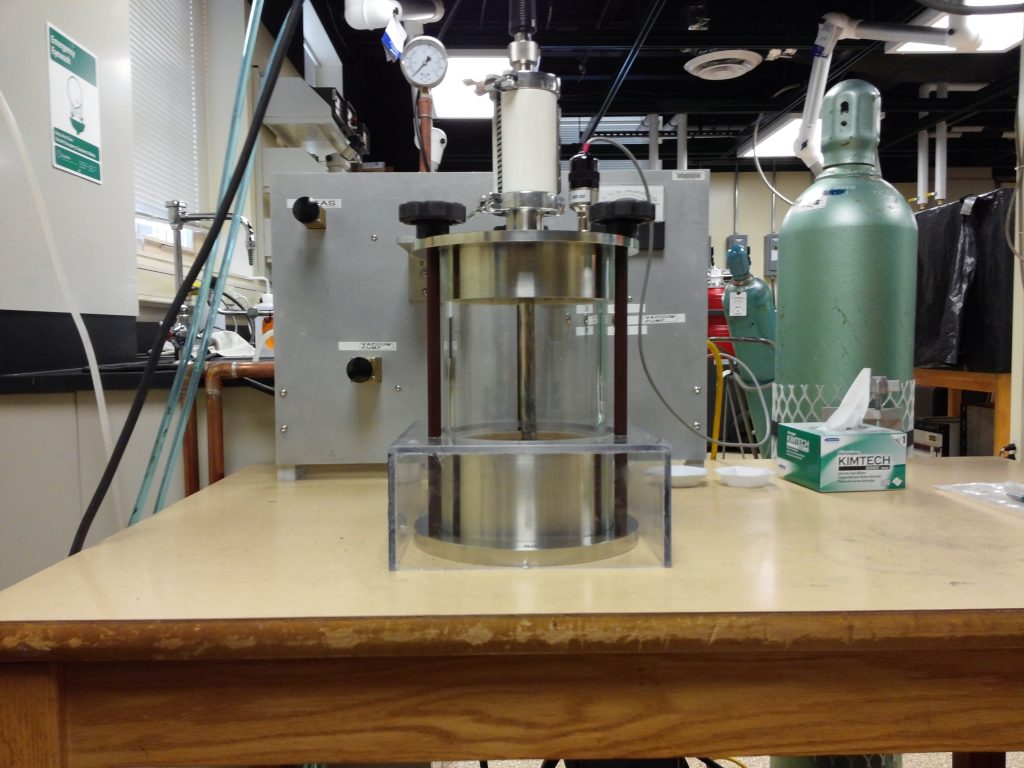

Sample Fabrication

My research lab specializes in the fabrication of polycrystalline alloys and compounds by arc melting and annealing techniques. The lab is equipped with an Arc Melter and multiple high temperature furnaces for the fabrication of these intermetallic systems. The samples are melted in a high purity argon atmosphere followed by annealing in high temperature electric furnaces.

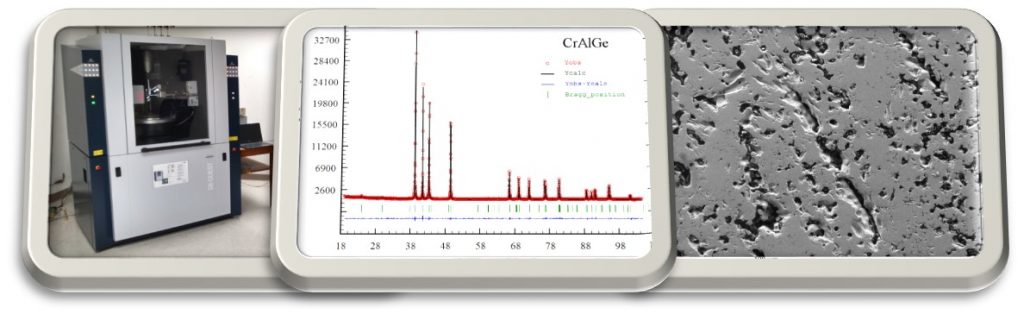

Crystalline properties determination

To determine the phase purity and crystalline structures all samples are subjected to x-ray diffraction (XRD) and SEM (scanning electron microscopy) measurements. The XRD measurements provide information regarding the crystalline properties like space group, crystal type, and lattice parameters. A Bruker D8 advance powder x-ray diffractometer is available at Miami University for the XRD measurements.

The SEM measurements are performed at the Center for Advanced Microscopy and Imaging (CAMI) at Miami University https://www.miamioh.edu/cas/academics/centers/cami/index.html. The center houses multiple SEM and TEM microscopes that are available for our research.

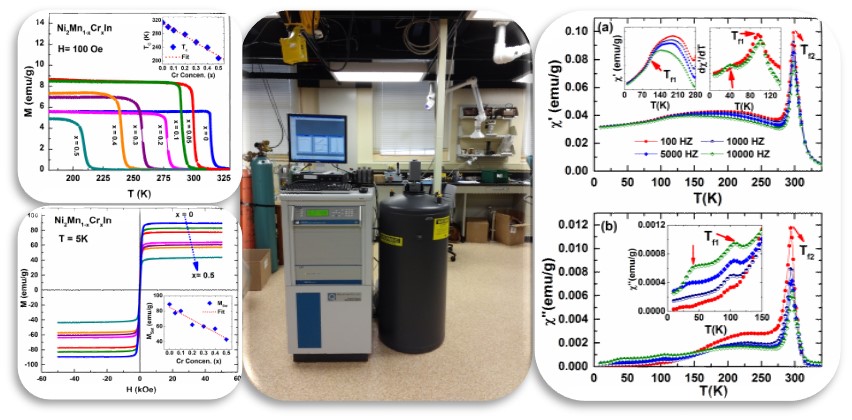

Physical Property measurements

For sample characterization, members of my research group conduct electrical resistivity, ac and dc magnetization measurements at various temperatures (between 1.8 K and 400 K) and magnetic fields (up to 9 T. Most of the measurements are performed on a Quantum Design Physical Property Measurement System (PPMS).

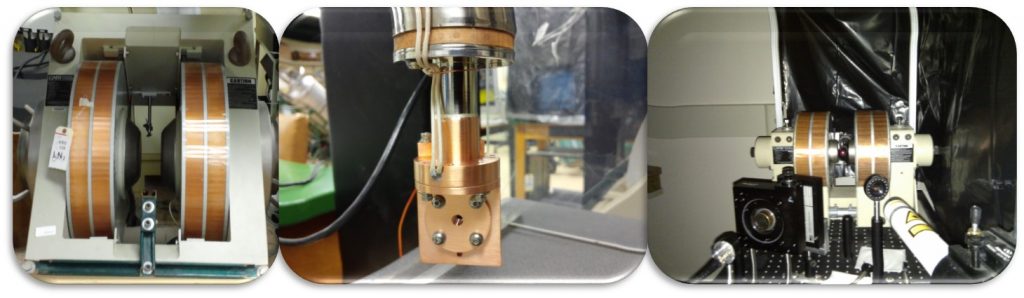

Additional Equipment

My research lab also houses additional equipment including a 3 T electromagnet, a cryostat-connected to a diffusion pump for electrical resistivity measurements (77 K – 450 K), and a setup for Magneto-optic Kerr Effect (MOKE) measurements. These apparatus are customizable for various type of measurements.