Hydraulic equipment pumps are essential in many industries and act as a practical means of transferring hydraulic fluid. In this article on gear pumps, we will examine their operational principles, principal parts, and typical uses to cover everything about them. Appreciating the way hydraulic gear pumps work exposes you to their pros and cons, thus increasing your understanding of hydraulics. This investigation will give beginners ideas and hands-on skills concerning the technology of gear pumps, whether one is an experienced engineer or just a student who wants more information about this subject.

What is a Hydraulic Gear Pump?

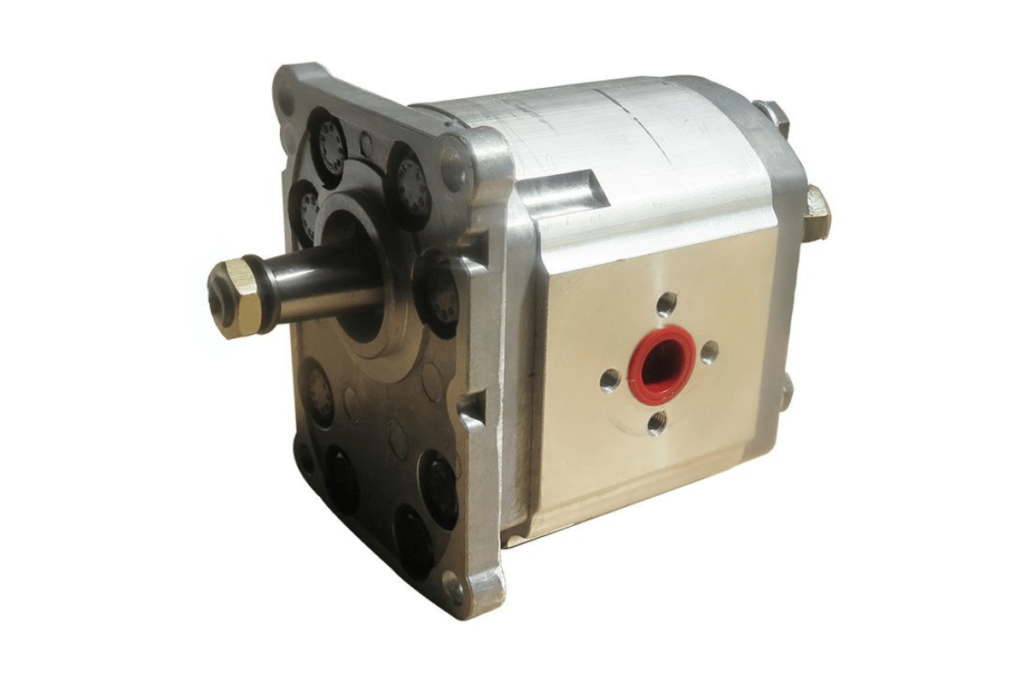

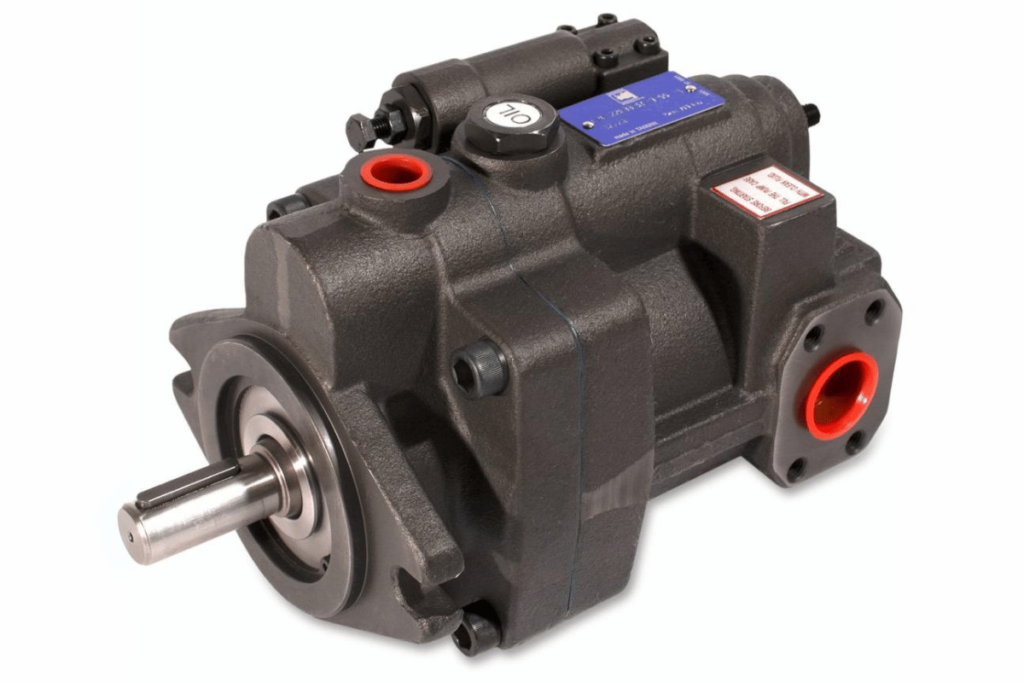

A hydraulic gear pump is a positive displacement pump that uses gears to move hydraulic fluid. Such pumps comprise two or more meshed gears that create a closed chamber, where one fluid is drawn in, and another gets displaced as these gears rotate. These types of pumps are straightforward and reliable while producing high pressure effectively. They can be seen mostly on mobile equipments like manufacturing machines etc., but also find usage within systems such as fluid power systems too. It should deliver uniform flow rates, usually over wide viscosity ranges, since it must handle different liquids commonly encountered in various industrial applications. Their robust design, coupled with operational efficiency, ensures that they are used widely across the board for most hydraulic needs, thereby guaranteeing the smooth transfer of fluids, which is necessary for completing tasks in this field.

Introduction to Hydraulic Gear Pumps

There are several points through which one can comprehend hydraulic gear pumps. Some of them include how they operate, their technical parameters, and application areas. Here’s a quick summary from various industry websites:

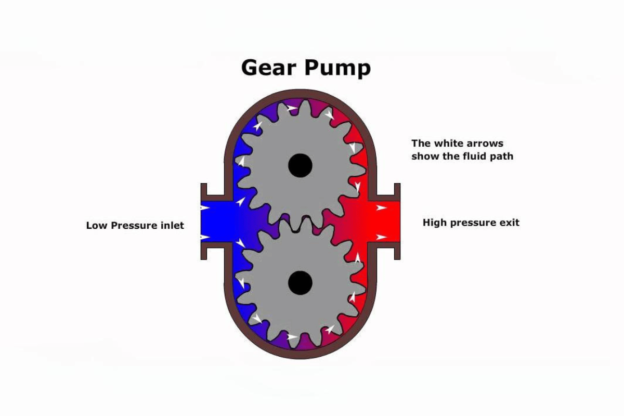

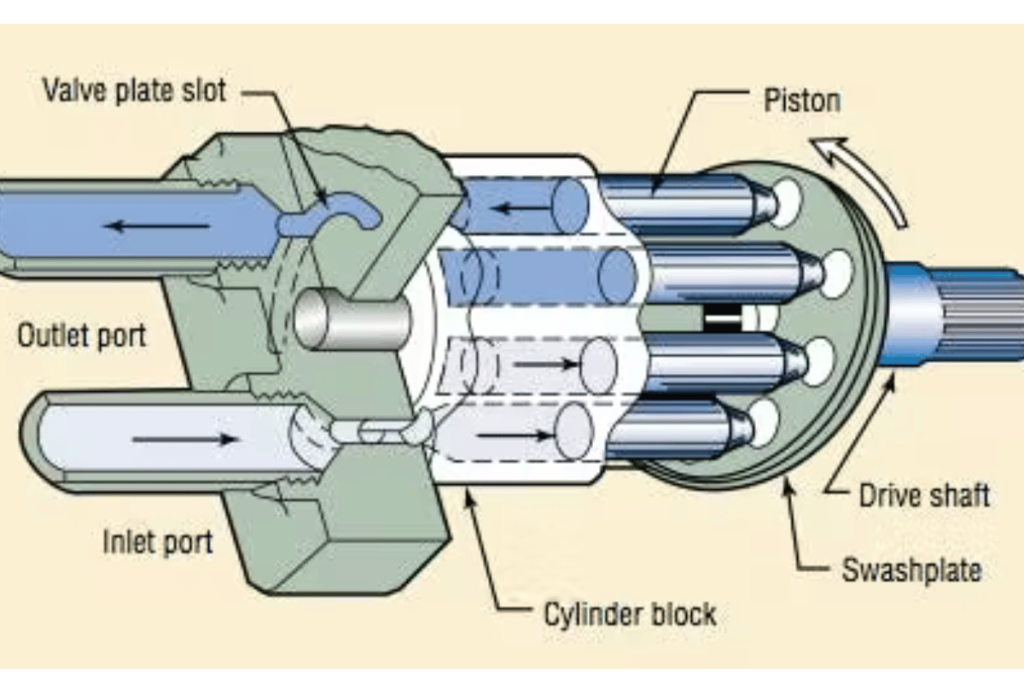

1. Operational Principles: Hydraulic gear pumps work on positive displacement, where two or more gears mesh together to draw fluid into a chamber and expel it. The vacuum created by rotating these gears allows the hydraulic liquid in a while pushing out displaced liquids.

2. Technical Parameters:

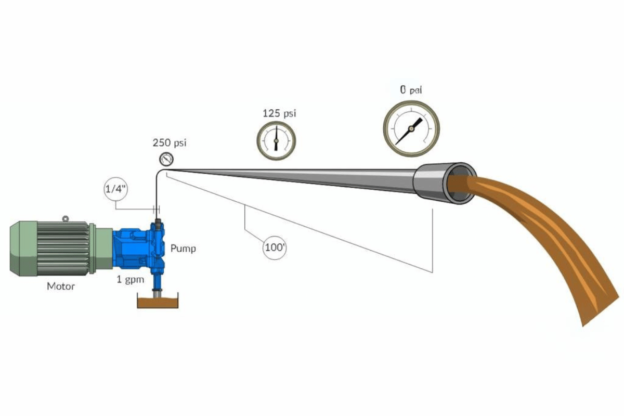

- Flow Rate: Usually between 1 – 500 gallons per minute (GPM) depending on pump size/design.

- Pressure Rating: Typically designed for pressures up to 3000 psi, some models can handle higher pressures.

- Efficiency: Normally, hydraulic gear pumps run at efficiencies ranging from 85% – 95% meaning that very little energy is lost during operation

- Viscosity Range: They can handle fluids with viscosities between 10 – 1500 centistokes (cSt), making them versatile for different applications.

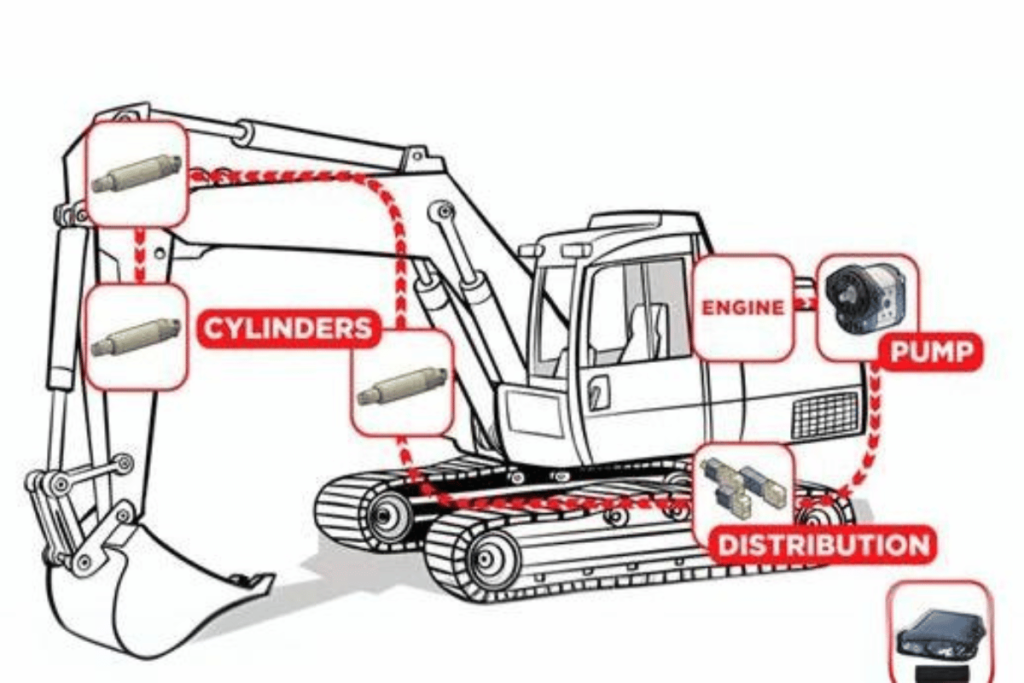

3. Common Applications: Known for their strength and ability to handle hydraulic power well, these types of pumps find wide use in construction (hydraulic excavators), the automotive industry (transmissions), and the manufacturing sector (CNC machines).

These are the basics upon which an individual can start understanding hydraulics gear pumps since, from this level, one may delve deeper into their specific roles within hydraulic systems.

Types of Gear Pumps: Internal and External

Gear pumps can be classified into two main types: internal gear pumps and external gear pumps. They have different applications and unique features.

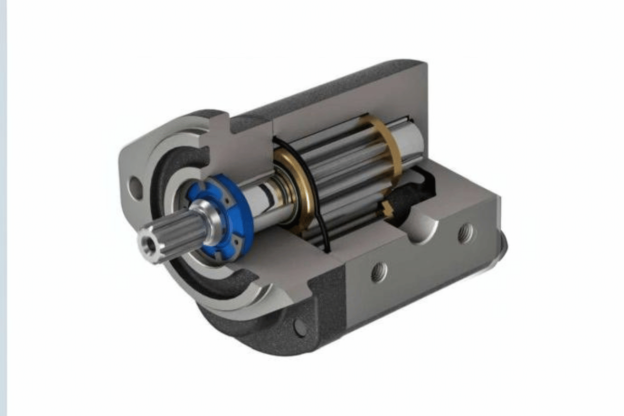

1. Internal Gear Pumps: A rotor and an idler working inside one casing. The rotor is eccentrically positioned, creating crescent spaces for fluid movement. Internal gears are famous for their ability to handle various viscosities while delivering an almost constant flow with slight pulsation. Usually, they work best at high pressures which makes them suitable for automotive and chemical industries among others where high pressure performance is required.

- Flow Rate: 1 GPM – 200 GPM (Dependent on Size & Application)

- Pressure Rating: Can Withstand Pressures up to 2500 PSI

- Efficiency: Typically Attains between 80% – 90%

- Viscosity Range: Suitable for fluids with viscosities from 30 cSt – 1200 cSt.

2. External Gear Pumps: In this design, the fluid is moved by two meshed gears rotating outside each other. This kind of setup is more straightforward than the internal type and is often used when dealing with lower-viscosity liquids. External gear pumps offer directness in construction reliability in terms of maintenance as well as providing high flow rates; hence, they are most commonly employed in industries involving large quantities, such as lubrication systems or fuel transfers for engines, etcetera.

- Flow Rate: 5 GPM – 400 GPM (Dependent on Configuration)

- Pressure Rating: Commonly Rated For Up To 3000 PSI

- Efficiency: Can Achieve Over 90%

- Viscosity Range Effective For Fluids With Viscosities Ranging From 1cSt –1000cSt.

Knowing these categories and their technical characteristics helps one choose the right pump for a given hydraulic system, thereby ensuring maximum efficiency coupled with reliability.

Applications of Hydraulic Gear Pumps in Industry

Hydraulic gear pumps are essential in many industries because they are efficient and can handle different viscosities. Here are some examples:

- Automotive Industry: Power steering and transmission systems use hydraulic gear pumps where high pressures with specific flow rates are necessary. Usually, they handle between 10 and 30GPM flow rates while tolerating up to 2500 psi pressure.

- Chemical Processing: They are used in the chemical industry to transfer corrosive or viscous fluids. Viscosities are limited between 30cSt and 1200cSt so that chemicals can move smoothly during production.

- Manufacturing Equipment: Hydraulic gear pumps inject molds or power hydraulic presses which help manufacturing machines work. These machines operate at different speeds but most fall within the range of 5-400GPM.

- Marine Applications: These pumps are used in hydraulic steering mechanisms and lifting equipment in marine vessels. Their ratings usually go up to 3000psi to ensure they work well under challenging conditions.

- Beverage Production: In the food and beverage industry, sweeteners, syrups, and oils need to be transferred, so hydraulic gear pumps come into play. Such a pump may handle fluids with viscosities ranging from one hundred thousandth poise (1cP) to one million poises(1MCP) without compromising health standards.

- Construction Equipment: Excavators and loaders, among other heavy machinery, require high flow rates coupled with large torques, thus necessitating the use of hydraulic gear pumps capable of delivering on those fronts.All construction works usually fall between 10 and 200GPM.

- Oil & Gas Industry: The transfer and processing of crude oil and lubricants greatly depends on these types of pumps. High-pressure resistant materials should be used because they can handle various fluid viscosities ranging around twelve thousand stokes(12000s).

- Agricultural Equipment: Hydraulic gear pumps are commonly used in tractors, harvesters and other agricultural machineries.They are similar to those used in construction works.

- Pharmaceutical Industry: Hydraulic gear pumps play a significant role in the pharmaceutical industry because they can handle different viscosities, which is handy when dealing with other pharmaceuticals.

- HVAC Systems: Hydraulic gear pumps circulate fluids, one of the many functions they perform in heating, ventilation, and air conditioning systems. They help maintain efficiency across various temperature settings.

The flow should remain constant at all times regardless of changes within the system being used, which requires it to be able to cope with various parameters.

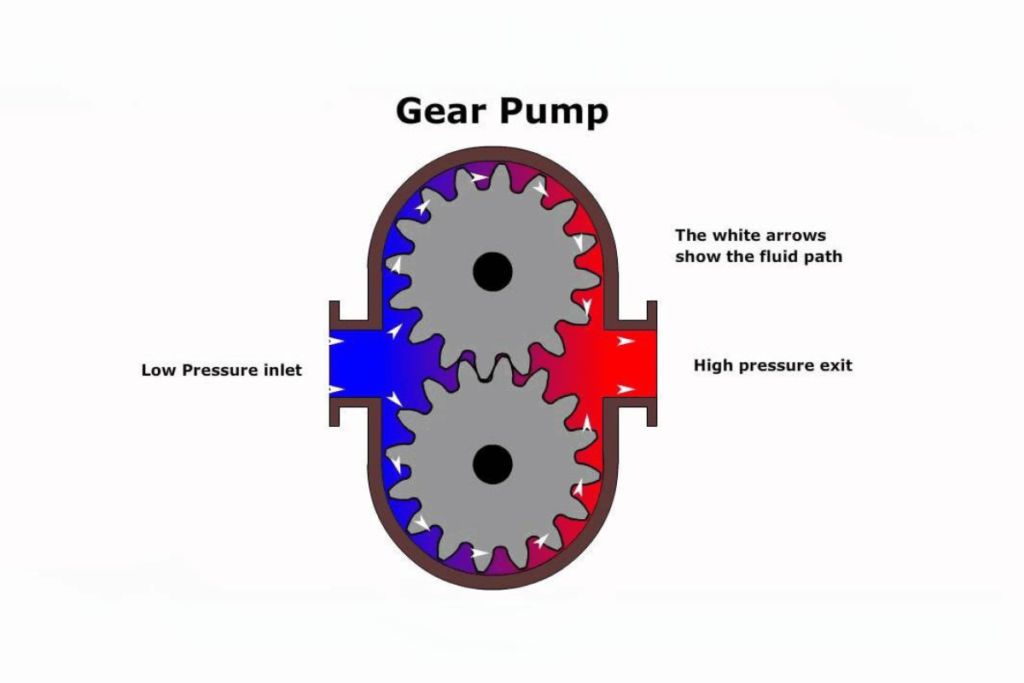

How Do Gear Pumps Work?

Hydraulic gear pumps work by a simple principle of positive displacement. They produce a vacuum as they rotate, which draws hydraulic fluid into the pump through its inlet. The liquid then occupies the clearance between gears and housing while they still move. Fluid is trapped and forced towards the outlet by the mechanical meshing of these components. Confined oil gets squeezed out under pressure at an exit port as one gear passes another. This process continues without interruption, supplying uniform flow rate of hydraulic liquid – making gear pumps highly efficient in different applications where reliability matters most among other factors affecting their performance such as design type used, clearance between moving parts involved and viscosity levels exhibited by pumped media among others needed parameters for successful operation with this type of machinery being considered reliable enough even at higher pressures commonly found within industrial environments where continuous delivery over extended periods becomes necessary.

Basic Working Principle of Gear Pumps

Positive displacement mechanism is the main principle of the working of gear pumps. When their teeth intermesh, they create cavities filled with liquid and then transferred from the input to the output. In this process, fluids are sucked by a rotating gear that causes a vacuum through its action. It then pushes them out as another comes into contact, maintaining continuous flow while trapping some amounts within itself.Several technical considerations should be taken into account, including:

- Flow Rate – It is usually expressed in gallons per minute (GPM) or liters per minute (LPM). It shows how much fluid can be moved by pump within a specific time period. Higher rates mean more work is done, thus making such devices efficient for most tasks.

- Pressure Rating—This refers to maximum operational pressures stated in Pounds per Square Inch (PSI) or Bar. An appropriate pressure rating must be chosen to handle the demands required by particular applications effectively.

- Viscosity—This measure denotes the thickness or thinness level exhibited by any given fluid being pumped, measured in centistokes (cSt). Gear pumps have a wide range adaptability, and some models can even pump up to several thousand centistokes depending on the different uses they may be subjected to.

- Efficiency Of The Pump – Usually expressed as a percentage signifying how much input power gets transformed into hydraulic energy outputted by said device. Greater efficiencies save energy during usage since lower percentages produce less heat while operating.

- Gear Design—Three common types of gears are used, namely spur, helical, and beveled. Each one has its own pros and cons, such as noise level production and efficiency rate achieved at various speeds. Different designs will suit different industrial needs based on the specifications required for use under certain conditions.

These parameters act as guidelines when selecting the appropriate gear pump for any given task, ensuring the best performance possible during all stages involved in various industrial processes.

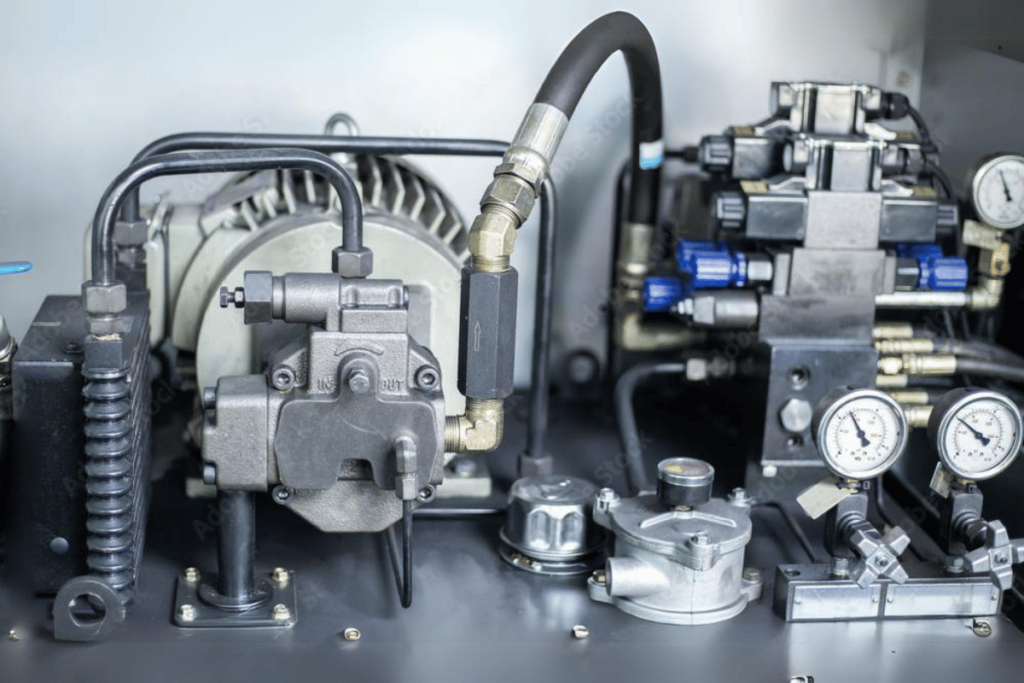

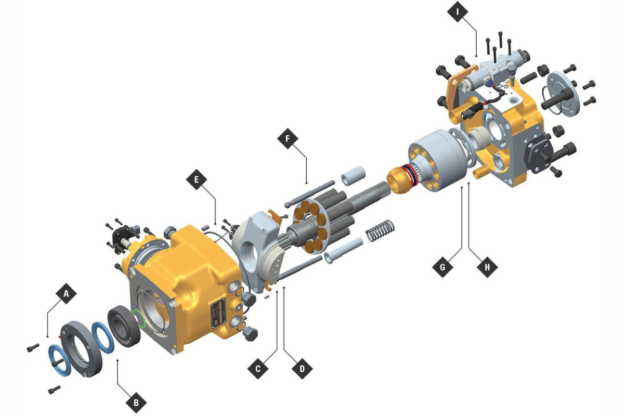

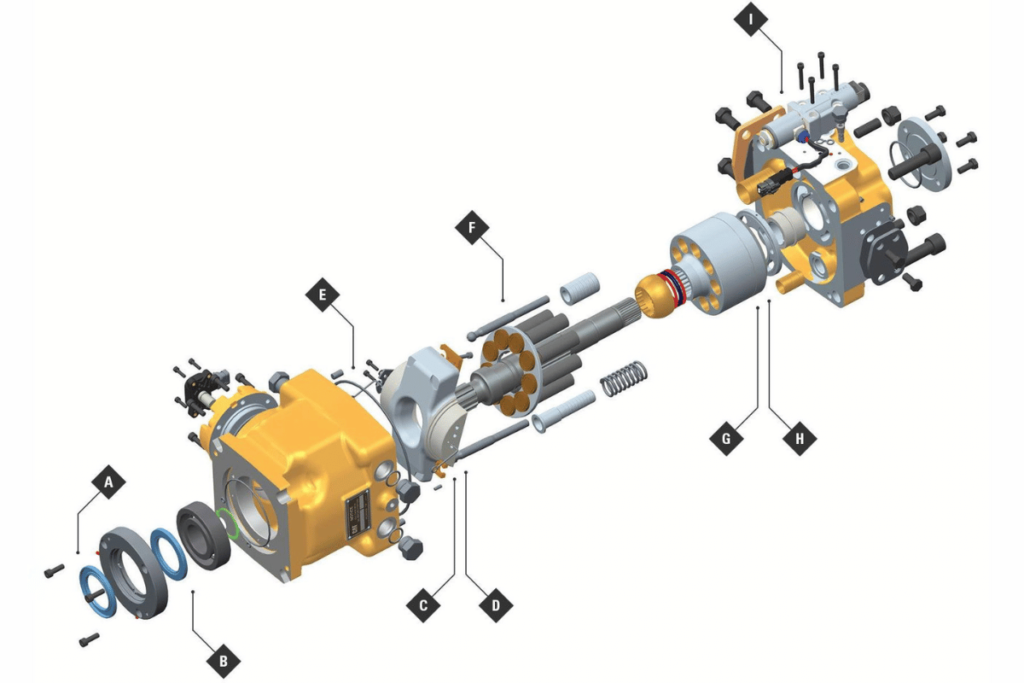

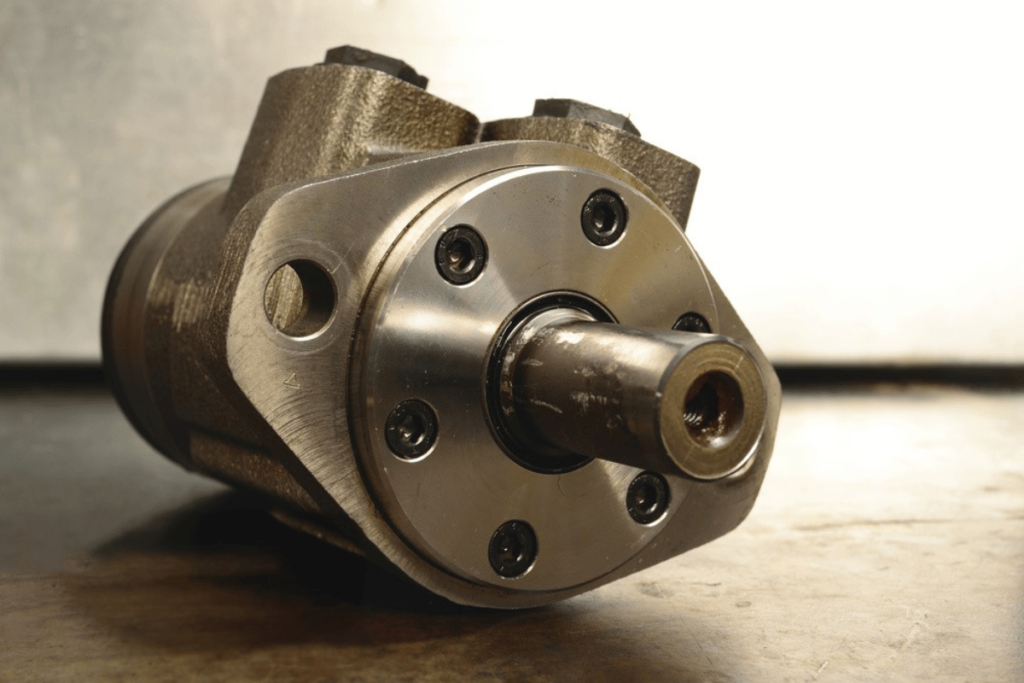

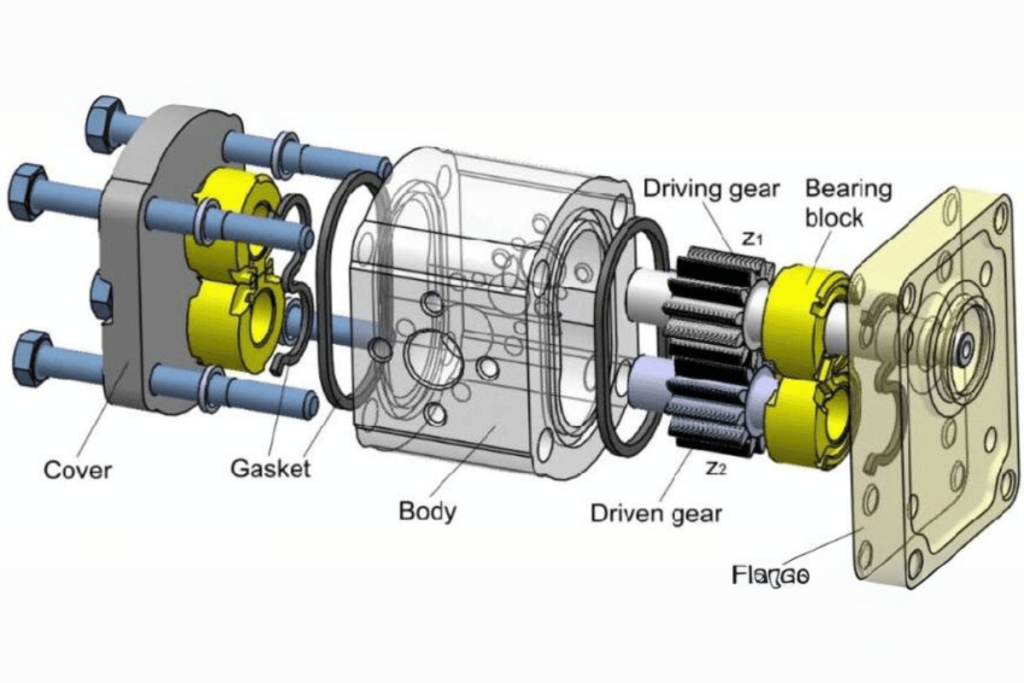

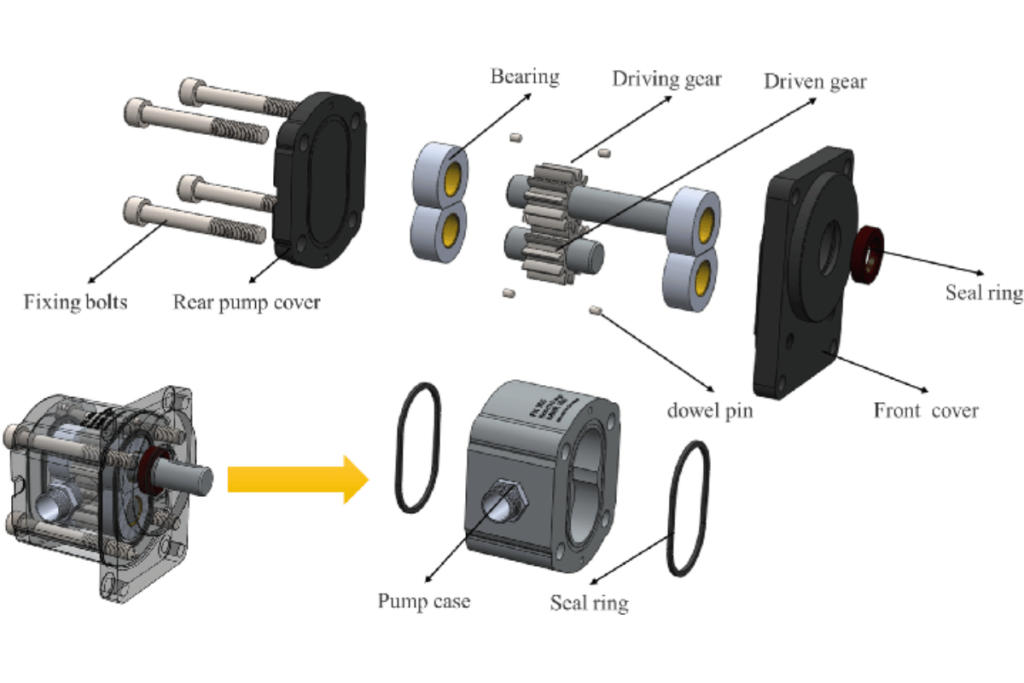

Critical Components of a Hydraulic Gear Pump

Hydraulic gear pumps are essential in many industrial applications, they can only be appreciated when we know what makes them perform effectively. Presented below are the main parts:

- Casing: The outermost part encloses all other components of a pump. It protects them from external forces and ensures the required internal pressure is maintained.

- Gears: These elements transfer hydraulic fluid. They are usually either straight-cut or helical, with each having its own advantages, such as lower noise levels during operation or higher efficiency rates.

- Suction and Discharge Ports: Openings through which liquid enters into and leaves out of the pump. Their design affects flow characteristics as well as efficiency.

- Bearings hold rotating gears in place within the unit’s housing. The right choice must be made for the longevity and stable operation of any bearing used here.

- Seals and Packing: These prevent hydraulic fluid from leaking out of a pump. Seals should remain intact to keep up pressure and contain fluids properly.

- Drive Shaft: This connects motor with a pump enabling rotation of gears. Its design should consider required torque while minimizing wear on itself or other parts involved.

- Pressure Relief Valve: It safeguards against over-pressurization by ensuring safe working conditions within the system, hence protecting against possible damages that may occur otherwise.

- End Plates: Gears are sandwiched between these plates, which also hold them in position, additionally providing support to overall structure integrity where necessary, such as preventing leakages through seals fitted on top surfaces thereof

- Flow Control Valve – regulates the amount speed at which oil flows throughout entire arrangement, thus enhancing effectiveness coupled with appropriate supply this kind energy where required, most being attained simultaneously =

- Cooling System – necessary for maintaining pump temperature levels within acceptable range, especially during extended use periods thereby optimizing performance life expectancy by large margin considerably too far longer than expected without such provisions or measures taken into consideration whatsoever

Thus, knowledge about these technical parameters, including but not limited to pressure ratings, efficiencies, and gear designs, among others, is important in selecting the right hydraulic gear pump for a particular task and maintaining it.

Fluid Flow and Gear Rotation Mechanism

The hydraulic gear pumps’ fluid flow and gear rotation mechanism is very essential to their operation. To put it simply, the rotation of gears produces a vacuum that sucks in liquid; this liquid then gets trapped between the teeth of the gears which carry it up to an outlet. Below are some critical technical terms associated with this process:

- Flow Rate: It is measured in liters per minute (L/min) or gallons per minute (GPM) and shows how much fluid is being displaced by the pump within specific time frames. Higher rates should be used where high demands are expected to increase efficiency.

- Viscosity: This characteristic measures how easily a fluid can move through something by resisting its flow; thus, it directly influences to what extent that particular fluid moves smoothly inside our pumps. Knowing range of viscosities suitable for your machine will significantly help you achieve better results

- Gear Ratio: The ratio between the number of teeth on the driven gear and the driving one determines the speed and torque required from them simultaneously. These two quantities must always balance each other out perfectly if we want everything else about the hydraulic system to function correctly. The proper selection made at this point enhances the overall efficiency levels attained by any given setup.

- Pressure Rating: This rating indicates the maximum pressure limit that different types of pumps can handle. It is usually expressed in pounds per square inch (PSI) or bar units, which is critical when choosing the appropriate pump for relevant applications.

- Efficiency Rating: Efficiency ratings show how well energy has been utilized during operation – they’re expressed as percentages where higher values mean good utilization and lower ones imply poor use. In other words, it compares input power with output power got from a given device under consideration i.e., Higher ratings indicate that more was supplied into system hence less operational costs incurred

These parameters ensure that the pump works effectively for its specific application without compromising reliability or lifespan. Failure to consider them could lead to a wrong choice being made among available options, hence ending all this knowledge about hydraulic gear pumps and what they can do for us.

Advantages and Disadvantages of Using a Gear Pump

Pros

- Efficiency: Gear pumps are good at pumping steady fluid flows, which makes them useful in various fields.

- Size: They are relatively small, which means they can fit easily into hydraulic systems without much modification.

- Adaptability: They work well with liquids of various viscosities i.e. from thin to thick consistency fluids.

- Long life: Due to their robust structure, these pumps can withstand heavy conditions and serve for a long time.

- No Pulsation: Gear pumps are handy in applications needing uniform pressure, as they deliver fluid steadily without pulsing.

Cons

- Priming Limitations: Setting up gear pumps may not be easy since most of them have to be primed before use, which complicates the installation and maintenance processes.

- Pressure Restriction: Some designs may not allow for very high pressure, hence limiting the areas where this type can be applied despite its capability in terms of pounds per square inch ratings (PSI).

- Viscosity Sensitivity: When viscosity levels significantly change, such machines affect performance and effectiveness.

- Wear Tear : Over time continuous interlocking gears will wear out thereby requiring regular replacements and servicing of parts used on such devices.

- Noise Production: Gear pumps might produce more noise pollution than other kinds, depending on the environment in which they are operated.

Benefits of Hydraulic Gear Pumps in Various Applications

Hydraulic gear pumps have gained popularity in many industries because they possess certain merits. These include:

- Uniform Output: They deliver a constant flow rate consistently which is necessary for accurate hydraulic control in applications like construction equipment and manufacturing machinery.

- Trim Size: These devices’ compact design makes them appropriate for use where space is limited, such as the automotive and aerospace industries, enabling more flexible system designs.

- Wide Range of Viscosity: Gear pumps can accommodate various fluid viscosities in industries like oil and gas, food processing, and pharmaceuticals, where different substances need to be pumped.

- Efficiency: Gear pumps are cost-effective, as they have low energy loss due to their high volumetric efficiency, making them suitable for energy-consuming operations.

- Reliability: This equipment is built strong enough to work under harsh conditions, so it can operate effectively in harsh environments like mining areas or agricultural fields, where machines are frequently subjected to rough treatments.

- Less Servicing Required: Unlike some complex types of pumps that may demand extensive maintenance on account of their intricate nature – this one does not require much attention because its design is simple though it wears out with time hence routine checks should be done.

- Sealing Capability: Hydraulic systems need to prevent leaks; therefore, any pump intended for use in such systems must possess good sealing properties to meet safety standards and environmental compliance—gear pumps excel here, too!

- Scalability: These gadgets allow both small and large-scale production setups, making them applicable across different sectors ranging from light-duty machinery to heavy industrial devices.

- Widespread Usefulness: Many people know about hydraulic gear pumps hence finding spare parts or servicing them is never difficult locally or internationally since numerous suppliers are dealing with these items worldwide which ensure quick availability wherever required.

- Cost-effectiveness – In most cases, initial costs associated with purchasing hydraulic gear pump tenders usually turn out cheaper over the long run due to their efficiency and reliability when compared to other pump types.

Gear pumps typically operate at pressures of up to 3000 psi or higher depending on the design as technical parameters. They come in different sizes for various flow rate requirements, usually ranging from a few liters per minute to over 1000 liters per minute. Hydraulic gear pumps can achieve efficiency levels of around 90% under optimum conditions, thus making them cost-effective across a wide range of applications.

Limitations and Challenges of Gear Pumps

While they have many benefits, hydraulic gear pumps also come with some limitations and challenges that users need to know about.

- Limited Viscosity Range: Gear pumps typically work well with low-viscosity liquids. However, they wear out more quickly or become less efficient when used with high-viscosity fluids, so it is necessary to select applications in such cases carefully.

- Pulsation and Noise: Gear pumps generate flow pulsations as they operate which can cause noise and vibration in a system. This may affect the performance of machines generally or increase their wearing rate over time.

- Temperature Sensitivity: Hydraulic fluids lose their lubrication properties under high temperatures, affecting pumping efficiency and causing thermal degradation. Operators should, therefore, monitor operating temperature levels to avoid overheating.

- Sensitivity to Contaminants: Gear pumps are easily damaged by dirt particles within them or dirty fluids passing through them. Therefore, the best thing to do is ensure a clean working environment throughout to achieve reliability and long-life service from these devices.

- Pressure Limitations: Gear pumps can handle a maximum working pressure of 3000 psi upwards, but exceeding this limit will cause the system to fail suddenly. Therefore, it is important to stick within specified operational boundaries while not overloading any part of the machinery beyond what it was designed for.

- Uneven Wear Patterns: Gear pumps sometimes wear unevenly, mainly if used with abrasive media. Therefore, frequent check-ups should be carried out, and worn-out components should be promptly replaced whenever necessary.

In conclusion, although they serve well in most areas as far as efficiency is concerned there still exist certain limits which one needs always take cognizance of and put proper corrective actions into place accordingly.

Comparison with Other Types of Hydraulic Pumps

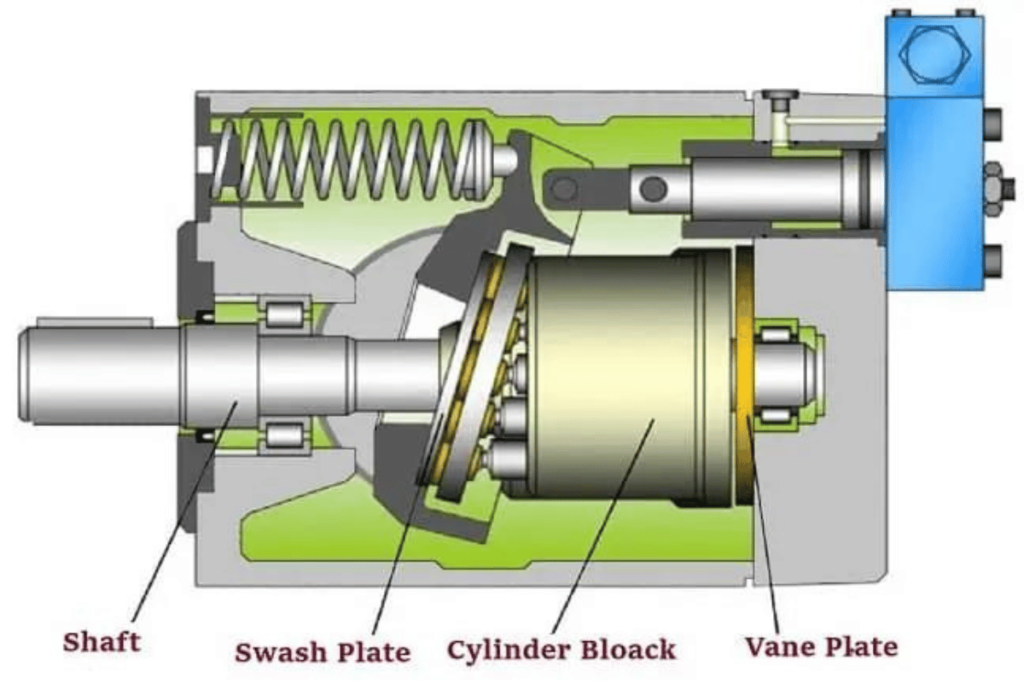

When we contrast gear pumps to other hydraulic pump types like vane pumps or piston pumps, it becomes clear that they differ in performance, efficiency and suitability for various uses.

- Piston Pumps: These types of pumps are best known for their ability to create higher pressures. They’re, therefore, commonly used where great force is needed. However, they are expensive and complicated compared with gear pumps which require less maintenance work that is more intricate. Also when the fluid flow changes constantly, their efficiency is better.

- Vane Pumps: operate more smoothly and quietly than gear pumps while still being able to handle different applications effectively. Nevertheless, just like the gear pumps, they become less efficient as viscosity changes. Additionally, self-priming capabilities are usually better for them than with gear pumps.

- Performance and Efficiency: Gear pumps are designed compactly to work well in environments with high viscosity levels while being durable; on the other hand piston or vane pumps could be more versatile under dynamic fluid conditions. Each pump has its own area of application where it can perform optimally, but constant flow requires a gear pump, whereas a piston pump should be used in systems with high pressures.

- Cost and Maintenance: For many industrial applications gears have lower initial costs and more straightforward maintenance requirements than pistons or vanes which also extend their life cycle thus reducing downtime significantly.

Knowing these differences will enable one to select the right hydraulic pump for his project, depending on specific needs and available resources.

Gear Pumps vs. Vane Pumps

Comparisons between gear pumps and vane pumps require the evaluation of various parameters that determine their applicability in different situations. Below is a brief summary from reputable industry websites:

1. Working Pressure:

- Gear Pumps: They can generally handle pressures of up to 5000 PSI, hence suitable for high-pressure applications.

- Vane Pumps: Typically function well within lower pressure limits around 1000-3000 PSI, which may restrict usage where demand is high.

2. Rate of Flow:

- Gear Pumps are known for providing uniform flow rates. Depending on size and speed, they give an extensive range of outputs, with a maximum flow rate generally exceeding 1000 GPM.

- Vane Pumps: Provide variable flows based on design, often ranging between 10 GPM and 500 GPM, which can change due to fluid viscosity.

3. Viscosity Capability:

- Gear Pumps: Designed for use with highly viscous fluids as they can pump thick liquids without experiencing much cavitation

- Vane Pumps are inefficient for handling fluids with high viscosity because their performance deteriorates as viscosity increases, resulting in reduced flow.

4. Maintenance:

- Gear Pumps: Standard maintenance procedures should be followed but this type has fewer movable parts, meaning less time spent on repairs leading to lower operational costs

- Vane Pumps: More intricate since they have rotating vanes necessitating frequent servicing and replacement of components

5. Costs:

- Gear Pumps: Relatively cheaper during initial purchase thus making them more cost-effective for many applications.

- Vane Pumps Have higher prices due to their complexity in design, but sometimes, this may be justified in cases where noise reduction or smooth running conditions are needed.

6. Noise Levels:

- Gear Pumps: Usually produce more noise when operating than vane pumps do.

- Vane Pumps: Operate quietly thereby favoring environments sensitive to sound disturbance.

These technical aspects are important in choosing between gear pumps and vane pumps based on application requirements, financial limitations, and performance expectations.

Gear Pumps vs. Piston Pumps

Comparing gear pumps and piston pumps involves looking at various technical parameters that affect their suitability for different applications. Below is a brief description of these parameters as per insights from top industry sources:

1. Flow Rate:

- Gear Pumps: They usually give constant flow rates that may vary between few gallons per minute (GPM) and over 1000 GPM. This even flow is suitable for applications that need steady pressure.

- Piston Pumps: The number of strokes and displacement volume of the pistons can be used to adjust the variable flow rates provided by this type of pump. It is therefore ideal for use when high pressure is required at specific intervals.

2. Viscosity Handling:

- Gear Pumps: Positive displacement devices are good at pumping high-viscosity fluids because they eliminate cavitation, which would otherwise disrupt continuous flow.

- Piston Pumpscan handle different viscosities, but their performance tends to deteriorate with very thick liquids, thereby reducing efficiency levels.

3. Efficiency:

- Gear Pumps: Gear pumps generally have high efficiencies, consuming less power, especially when dealing with low-viscosity fluids.

- Piston Pumps: Specific applications can achieve high efficiency, mainly by generating substantial pressures; however, a continuous duty cycle may not be as efficient as a gear pump.

4. Maintenance:

- Gear Pumps: These types of pumps require less maintenance because they have fewer moving parts, lowering operational costs and minimizing downtime.

- Piston Pumps: Because their design is complex, maintenance frequency might increase along with repair needs. Seals and pistons wear out easily during operation, leading to frequent breakdowns or replacements, thereby increasing downtime durations.

5. Cost:

- Gear Pumps: They have lower initial costs than piston pumps making them more affordable across different uses.

- Piston Pumps: Due to their intricate nature, piston pump systems require higher upfront investments compared to gear pump systems, though such expenses may only be justified under certain performance conditions based on specific application requirements.

6. Noise Levels:

- Gear Pumps tend to be noisy during operation, which can be a challenge in environments that are sensitive to noise pollution.

- Piston Pumps: Quieter operations make it better suited for places where one needs to minimize unwanted sounds.

When choosing between gear and piston pumps, these technical parameters should be considered relative to the particular application so that the selected pump can effectively satisfy operational needs while considering cost.

Choosing the Right Pump for Your Needs

When you are choosing a pump for your particular application, some technical parameters have to be considered according to your operational needs. After looking at the best online resources available out there, these are the main points to weigh up:

1. Application Type:

- To determine which pumps are suitable, determine if it is for low-viscosity fluids, high pressure, or continuous use.

2. Efficiency Requirements:

- Gear Pumps can save energy when used in low-viscosity fluid applications although piston pumps work well under such conditions especially where high pressures must be realized.

3. Maintenance Considerations:

- Evaluate maintenance requirements based on your environment. Gear pumps would suit this need if you need reduced downtime and operating costs. They have few moving parts, so less maintenance is required. Conversely, if frequent servicing can be done within the system being used, select piston pumps because of their potential in high-performance areas.

4. Cost Analysis:

- Look at both upfront and life cycle expenses involved. While initial investment may favor gear pumps over piston ones, which might look expensive initially but perform better in high-performance areas, thus saving money over time.

5. Noise Level Impact:

- Consider surrounding conditions. If noise happens to be a major factor of concern, then use piston pump systems. They are silent, making them ideal for delicate environments. However, gear types should not be ruled out just yet, as they still possess other advantages.

By systematically considering these factors one by one, you can make technically sound decisions and save on costs through proper maintenance measures.

Future Trends in Hydraulic Gear Pumps

Many new trends are expected to influence the future of hydraulic gear pumps. These shifts coincide with evolving technology and industry needs. One such trend is a focus on energy efficiency, which has prompted manufacturers to create higher-performance pumps that use less power. This demand aligns with broader efforts across sectors to lower carbon footprints and save money on operations. Furthermore, real-time data analysis enabled by Internet of Things (IoT) integration is transforming pump monitoring and maintenance through predictive upkeep and reduced downtimes.

Additionally, the drive for smaller sizes and lighter weights in mobile applications or tight spaces where efficiency and space-saving designs matter most is gaining momentum. Finally, sustainability is becoming essential with more companies looking into environmentally friendly materials or processes used in making hydraulic pumps. Such trends indicate a changing landscape for this sector as it responds to global calls for greater efficiency coupled with technological advancements.

Innovative Designs in Gear Pump Technology

Gear pump technology is improving quickly to match the demands of current industries. These improvements include making high-torque gear pumps, which have higher flow rates without losing efficiency. This type of pump usually has well-made gears that reduce internal friction, thus saving energy and reducing noise.

Another change is creating a variable displacement mechanism that allows pumps to vary their output according to demand, saving energy and making systems more responsive. Furthermore, science has developed new materials, such as composites and lightweight ones, which are used in building them. This helps in reducing their overall weight while increasing durability as well.

Parameters

- Torque Rating: Higher torques ratings enable pumping highly viscous fluids at more significant flows with increased efficiency.

- Displacement: Variable displacements may better match a pump’s output and the system’s needs, optimizing performance.

- Efficiency Rating: Better designs often mean less power consumption, reflected through higher efficiency ratings.

- Noise Level: More refined engineering methods lead to quieter operations, especially necessary for a calm environment.

- Material Properties: Advanced materials can increase wear resistance, protecting against corrosion and increasing the lifespan of these machines.

These changes indicate our efforts towards operational effectiveness, environmental sustainability, and reliability improvement in hydraulic systems.

Environmental Impact and Energy Efficiency

In their design and operation, one of the most important things to consider about hydraulic pumps is how they affect the environment. These developments for energy efficiency are cost-effective and help reduce the carbon footprint that comes with using a pump. Here are some of those strategies:

- Variable Displacement Mechanisms: By allowing the output of a pump to change depending on what’s needed, these mechanisms save power while reducing wastage through it which means lower emissions and more sustainable development.

- High Torque And Efficiency Ratings: Higher torque ratings enable better handling of highly viscous fluids, thus cutting down on energy consumption required for this purpose. Eventually, this will result in low power usage. Pumps with good efficiency rates will demand less energy, leading to reduced greenhouse gas emissions.

- Noise Levels Reduction: Enhanced engineering can make pumps quieter during operation and less destructive to wildlife or people around them, thereby fostering a better relationship between man and nature.

- Advanced Materials: When materials that do not wear off easily due to corrosion are used in making these machines, it not only extends their lifetime but also decreases the frequency with which they need replacing; hence, over time, fewer resources will be consumed as well as generate less waste.

Manufacturers who design hydraulic pumps based on these technical specifications show an interest in sustainability, which further improves the overall environmental performance of their products.

Predictions for the Hydraulic Pump Market

According to technological advancements and increasing demand from different sectors, the hydraulic pump industry is anticipated to achieve substantial growth in the future. The predictions are as follows:

- More use of intelligent systems: It is predicted that there will be more adoption of Internet of Things (IoT) devices in hydraulic pumps. These devices allow for real-time monitoring and prediction of maintenance requirements, thus making operations efficient while minimizing downtime. The technical parameters involved here comprise sensors used in monitoring pressure and flow rate, which provide information necessary for optimally managing performance.

- Shifting to mobile and compact solutions: As industries look towards improving their flexibility and portability, they should expect an increase in mobile hydraulics. These are designed with lightweight features besides being smaller in size but still having high torque outputs that can handle heavy-duty applications effectively.

- Sustainable Innovations: Environmental consciousness has led people to think about sustainable development, even when designing such products. Therefore, we may witness pumps with better energy ratings, those that meet emission standards set by regulatory bodies among other things, characterized by extended life span courtesy of advanced materials utilization being introduced into this market soon enough

- Renewable energy application emergence: Hydraulic power systems have found themselves helpful within renewable energy areas, especially during wind or even hydroelectricity generation stages, where variable displacement type high-performance units must be employed to save energy and ensure efficiency.

- Market consolidation & collaborations: Manufacturers could join hands through partnerships to create innovative solutions, thereby reshaping industry competitiveness through mergers expected between some companies and other moves within this segment. Collaborative ventures focusing on research coupled with development activities might result in breakthroughs concerning efficiency metrics together with advanced material application, thus improving overall quality standards alongside environmental friendliness relating to hydraulic machines.

Overall, sustainability needs, while addressing these trends, can help shape production models within the hydraulic sector, hence meeting new demands from various sectors supported by appropriate technical specifications.

Frequently Asked Questions (FAQs)

1. What are the main applications of hydraulic pumps?

Hydraulic pumps are widely used in various industries, including construction, agriculture, manufacturing, and renewable energy. They are essential for powering machinery, hydraulic systems, and equipment that require fluid power for operation.

2. How do I choose the right hydraulic pump for my application?

Selecting the appropriate hydraulic pump involves considering several factors, such as the required flow rate, pressure rating, and the viscosity of the hydraulic fluid. Additionally, evaluating the specific operational requirements of your machinery and considering factors like size and energy efficiency are crucial.

3. What advancements are being made in hydraulic pump technology?

Recent advancements in hydraulic pump technology include the integration of intelligent sensor systems for real-time monitoring, the development of compact and lightweight designs, and innovations geared toward enhancing energy efficiency and sustainability.

4. How do hydraulic pumps contribute to sustainability?

Hydraulic pumps aid sustainability through improved energy efficiency, reduced emissions, and the use of eco-friendly materials. Their role in renewable energy applications also supports the transition to greener energy sources.

5. What maintenance is required for hydraulic pumps?

Regular maintenance of hydraulic pumps includes checking fluid levels, inspecting for leaks, cleaning filters, and ensuring all components function correctly. This helps extend the pump’s lifespan and ensures efficient operation.